- Online Shopping Coming Soon

In the world of textile manufacturing, precision and creativity are paramount.

Weaving intricate and complex designs requires the use of advanced machinery, and one such machine that has revolutionised the industry is the electronic jacquard machine.

Unlike its mechanical predecessor, the electronic jacquard machine combines the power of digital technology with weaving expertise to create stunning and intricate textile designs.

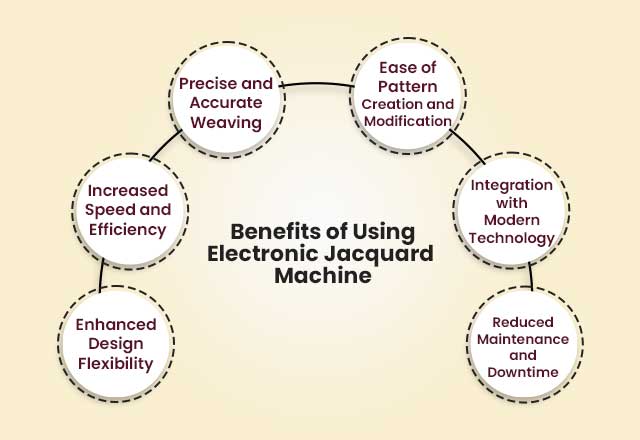

The emergence of electronic jacquard machines has revolutionised the industry, offering numerous advantages over traditional mechanical counterparts.

In this blog, we will highlight the key benefits of using electronic jacquard machines.

Electronic jacquard machines provide unparalleled design flexibility. Unlike mechanical jacquard machines, which are limited in terms of pattern complexity, electronic jacquard machines can produce intricate designs with ease.

Through digital control and pattern generation, these machines can weave elaborate motifs, intricate details, and even photographic images. This flexibility opens up endless creative possibilities for textile designers and allows for customization on a whole new level.

One significant advantage of electronic jacquard machines is their improved speed and efficiency. Traditional mechanical jacquard machines require manual adjustments for each design change, which can be time-consuming and labour-intensive.

Electronic jacquard machines, on the other hand, automate the design selection process, enabling swift pattern changes without the need for physical alterations. This not only speeds up production but also increases overall efficiency, allowing for higher output and reduced downtime.

Precision and accuracy are crucial in the textile industry. Electronic jacquard machines excel in this aspect. With their electronic control systems, these machines offer precise control over each individual warp thread, ensuring consistent and accurate weaving. This level of control eliminates errors and imperfections that may occur with mechanical machines, resulting in high-quality textiles with impeccable designs.

Creating and modifying patterns is simplified with electronic jacquard machines. Advanced computer-aided design (CAD) software allows designers to digitise their patterns, making it easier to visualise and manipulate designs.

With just a few clicks, patterns can be modified, resized, or combined, saving significant time and effort compared to the manual process involved with mechanical machines.

Electronic jacquard machines seamlessly integrate with modern technology, unlocking a plethora of possibilities. These machines can be connected to computer systems, enabling direct transfer of designs and patterns, reducing human error, and ensuring consistency.

Moreover, electronic jacquard machines can be integrated with other automated processes in textile manufacturing, such as loom control systems and robotic fabric handling, creating a synchronised and efficient production environment.

Mechanical jacquard machines often require frequent maintenance and adjustments due to wear and tear on mechanical components. In contrast, electronic jacquard machines have fewer moving parts, resulting in reduced maintenance needs and downtime. The electronic control systems are highly reliable and require minimal upkeep.

Electronic jacquard machines have transformed the art of weaving by combining digital control, design flexibility, and precision. These machines have opened up a world of possibilities for textile designers and manufacturers, enabling the creation of intricate and elaborate designs with ease and efficiency.

Copyright © Golden Elegance. All Rights Reserved. Website Development & Digital Partner – BUSFAM