- Online Shopping Coming Soon

Weaving is the operation of making fabrics by intertwining the threads lengthwise and widthwise which are known as warp and weft in a regular order. The procedure is performed in a weaving machine called a loom. The process consists of two sets of yarns that are always at right angles to each other.

Weaving any fabric has a long preparation process that involves winding, warping, sizing, drafting, denting, and finally weaving. Different fabrics are produced in different weaving machines in the textile industry. It includes woven fabric, knitted fabric, and non-woven fabric. If you are looking for weaving machines, contact the trusted weaving machine manufacturers, Golden Elegance now.

The different machines which are normally used in these processes are listed in this article.

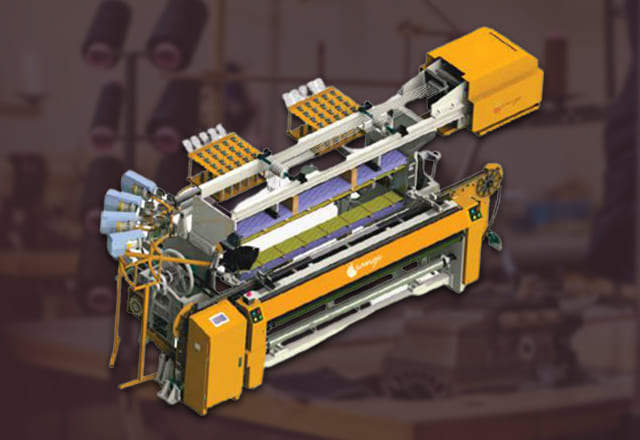

Rapier looms are weaving machines which act as the means of carrying the weft through the shed. It is fastened at the end of a rod or in a flexible ribbon being positively driven.

A rapier loom may have a single rapier to hold the weft over the full width or a single rapier processing bilaterally with a central pivoted weft supply, or two rapiers operating either sides of the machines.

Rapier looms are of many types. Early models use one long rapier device that goes along the width of the loom to carry the weft that moves between the sides. Another type of rapier loom consists of two rapiers, one on each side of the loom. They are rigid, flexible or farsighted.

Electronic jacquard machines are utilised as automatic controls to replace mechanical jacquard weave. The control system of an electronic jacquard machine has one electromagnetic needle selector, one controller and one angle detector. The controller of the machine consists of one data read or write interface circuit, one memory and one embedded processor or includes one radio data transmission module, one non-volatile memory and one embedded processor.

The processed weaving pattern information is stored in the movable memory of the machine so that the control system of the electronic jacquard machine processes them to weave the desired fabric.

The velvet loom is a loom that weaves a double layer of fabric which is needed by the structure of velvet. Between the top and bottom layers there exists a certain length of pile warp. The two layer fabric later gets cut apart and forms two velvet fabric.

The loom is said to adopt the intelligent velvet control system, which can realise the functionalities of electronic set-off for ground warp and pile warp respectively.

Dobby is a machine that sheds motion in the loom. Dobby shedding motion is used to weave different kinds of weaving patterns. Every heald shaft is raised and lowered in an unlike pattern in dobby shedding. Generally 20 head shafts are used in a dobby but in some dobbies, 28 to 48 jack levers are used. Small motifs and geometrical weave patterns are woven on these looms.

Copyright © Golden Elegance. All Rights Reserved. Website Development & Digital Partner – BUSFAM