- Online Shopping Coming Soon

The textile sector has witnessed a profound revolution through the integration of automation and robotics into its processes. Notably, the incorporation of these technologies into textile looms has been instrumental in elevating efficiency, precision, and overall productivity.

This article delves into the importance of automation and robotics in textile looms, spotlighting the technological strides that have reshaped the textile manufacturing panorama. Moreover, it accentuates the role of these advancements in weaving training, emphasising how automation and robotics contribute to refining the skills and techniques essential for intricate and precise weaving processes.

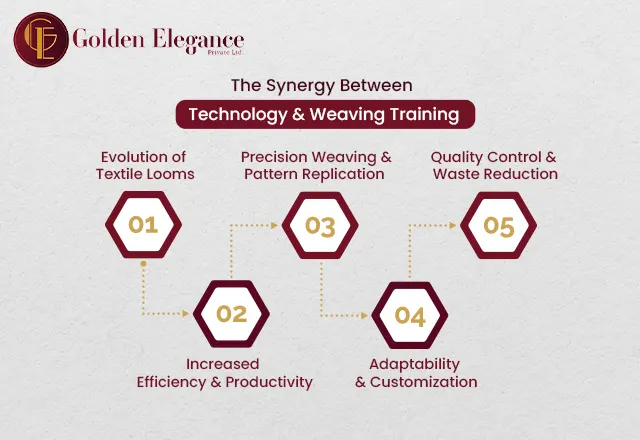

The synergy between technology and weaving training is at the forefront of transforming the textile industry into a more dynamic and skill-centric domain.

Historically, textile looms were operated manually, requiring skilled labour for weaving intricate patterns. As technology progressed, semi-automatic and automatic looms emerged, reducing the dependence on human intervention. However, the recent surge in automation and robotics has catapulted textile looms into a new era of efficiency and innovation.

Automation and robotics in textile looms have significantly increased production efficiency. These technologies enable continuous, high-speed operation, minimising downtime associated with manual interventions. Automated looms can handle repetitive tasks with precision, resulting in a consistent and high-quality output. This boost in efficiency has a direct impact on the overall productivity of textile manufacturing.

One of the key advantages of incorporating robotics in textile looms is the ability to achieve unparalleled precision in weaving. Advanced robotic systems can execute complex patterns with accuracy, ensuring uniformity in the final product. This level of precision is particularly crucial in industries where intricate designs and patterns are in demand, such as high-end fashion and technical textiles.

Automation and robotics have made textile looms more adaptable to diverse production requirements. These systems can quickly switch between different fabrics and patterns, allowing manufacturers to meet the demands of a rapidly changing market. The ability to customise designs and respond swiftly to market trends gives businesses a competitive edge in the dynamic textile industry.

Robotic systems integrated into textile looms come equipped with advanced sensors and monitoring capabilities. This facilitates real-time quality control, identifying defects or irregularities in the weaving process. By detecting and addressing issues promptly, manufacturers can minimise waste and ensure that only high-quality products reach the market. This not only improves the bottom line but also enhances the brand reputation for delivering top-notch products.

In short, adding automation and robotics to textile looms has completely changed how we make textiles. We moved from doing things by hand to using automatic systems, which has made things much better. Now, we can produce things more efficiently, weave with more precision, adapt to changes easily, and make sure our products are of top-notch quality.

As technology keeps getting better, automation and robotics in textile looms will become even more important, letting us do more than ever before. Weaving training, where people learn how to weave using these new technologies, is a big part of this change. It’s like combining what people know with what machines can do, and it’s leading the textile industry towards a future where being fast, precise, and adaptable is key, making weaving training a crucial part of the textile world.

Copyright © Golden Elegance. All Rights Reserved. Website Development & Digital Partner – BUSFAM