- Online Shopping Coming Soon

In the world of textiles, few fabrics evoke the same sense of opulence and luxury as velvet. Renowned for its soft, plush texture and rich appearance, velvet has a timeless allure that has captivated fashion designers, interior decorators, and textile enthusiasts for centuries.

Behind the scenes of this exquisite fabric lies a marvel of engineering—the velvet weaving machine.

In this blog, we’ll delve into the intricate world of velvet weaving machines, exploring their history, mechanics, and the artistry that goes into creating these sumptuous textiles.

Velvet has a storied history that dates back to ancient civilizations, with evidence of its existence found in regions like China and Egypt. However, it wasn’t until the Middle Ages that velvet weaving became a refined craft in Europe, particularly in Italy. Traditional velvet weaving involved labour-intensive processes, including hand-weaving and hand-tying individual threads to create the plush pile characteristic of velvet.

The advent of industrialization in the 19th century revolutionised textile production, paving the way for the development of velvet weaving machines. These machines automated the weaving process, significantly increasing efficiency and output while maintaining the intricate details that make velvet so alluring.

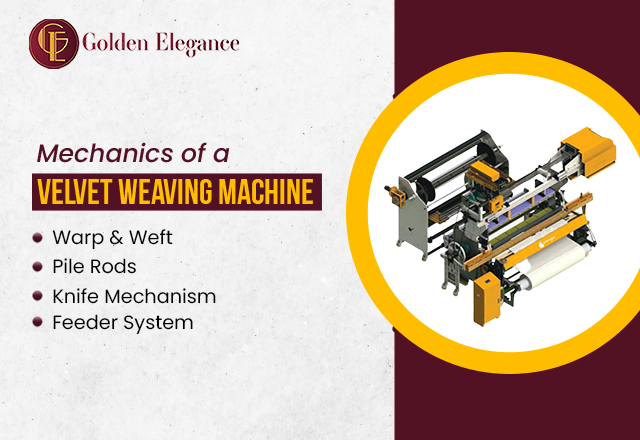

Modern velvet weaving machines are marvels of precision engineering. They consist of various components working in harmony to transform raw materials into the luxurious velvet fabric we adore.

While velvet weaving machines have streamlined the production process, the artistry involved in crafting exquisite velvet remains. Designers and artisans collaborate to create intricate patterns and textures, pushing the boundaries of what velvet can achieve. From traditional floral motifs to contemporary geometric designs, the versatility of velvet allows for a wide range of creative expression.

Velvet weaving machines stand as a testament to the seamless integration of art and technology in the textile industry. As these machines continue to evolve, they enable the creation of velvets that are not only luxurious but also sustainable and accessible. The allure of velvet, with its timeless elegance and tactile indulgence, remains undiminished, and the velvet weaving machine ensures that this cherished fabric continues to grace runways, homes, and beyond, weaving a legacy of sophistication that transcends time.

Copyright © Golden Elegance. All Rights Reserved. Website Development & Digital Partner – BUSFAM